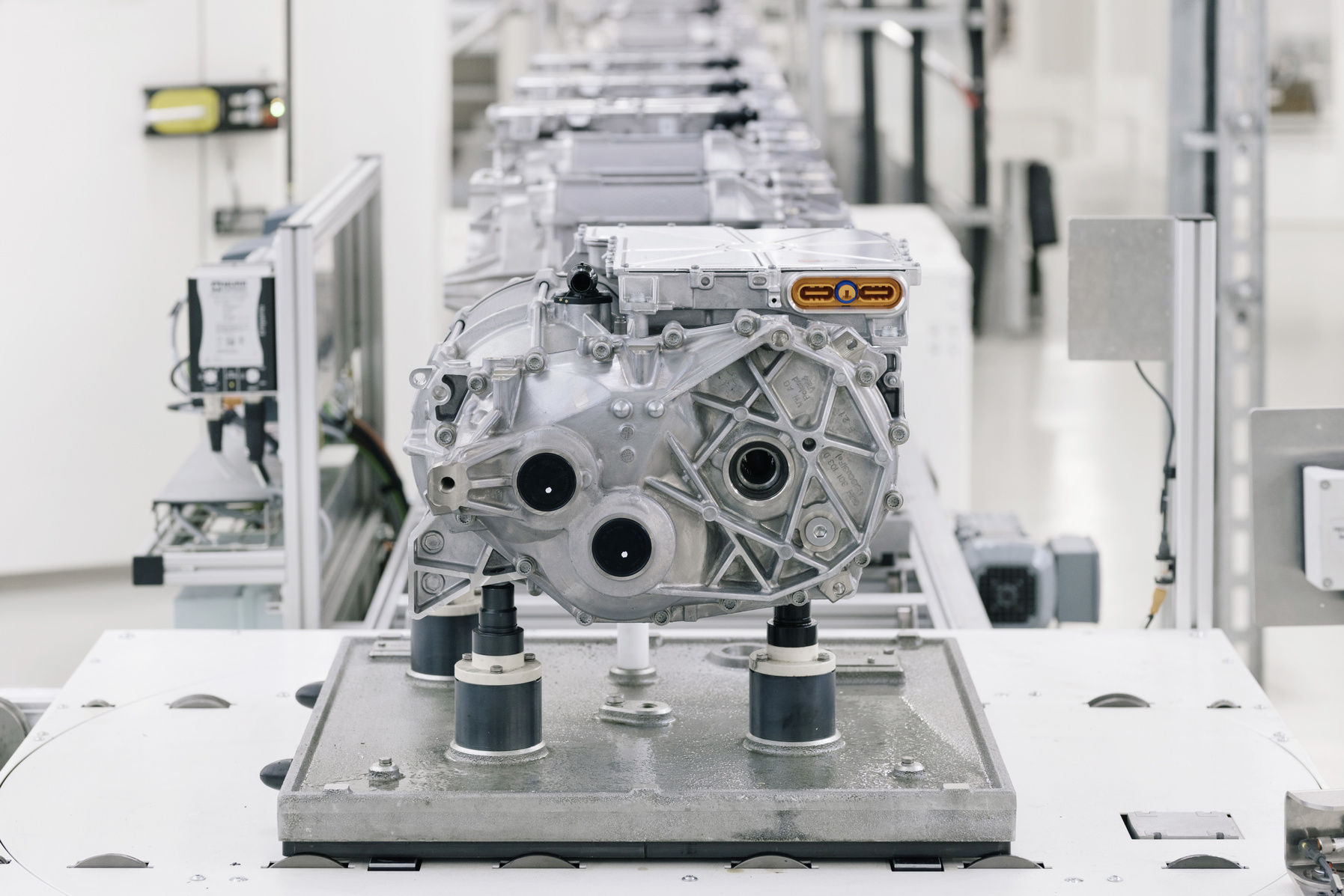

Audi chooses Støtek to increase their furnace reliability and metal quality

Leading German automobile manufacturer, Audi was looking for a modern, sustainable, and trusted way to create high-quality automotive parts in...

Støtek has years of experience working with the automotive industry, which has brought along a great amount of knowledge and insight as to what matters when manufacturing components for the automotive industry. We often receive feedback from our customers, showcasing exactly what features of our furnaces have made a particular impact on their production.

No one knows how our furnaces work with customers' specific production lines better than the customers themselves. Therefore, we consider feedback and dialogue to be of extreme value and importance to us.

Part of our value chain is that we stay in contact with our customers post-delivery. We do this to build long-lasting relationships that are based on mutual trust, service, and support.

We invest in our customers and through dialogue and support, we receive feedback and constructive insights that make us more knowledgeable in terms of our furnaces' impact on the production facilities for our customers. This not only allows us to constantly improve our furnaces, it further enables us to get acquainted with our customers' approach and production needs to provide the best possible service in the future.

The innovative integration of the Dosotherm® DTI furnace brings several advantages such as ultra-precise dosing technology with immersion heating, exceptional productivity, and quality.

Through constant feedback and dialogue, we have experienced that our Dosotherm® DTI furnaces have brought particularly good results. We have gathered some of the most prominent remarks to highlight the results that stood out the most to one of our larger automotive customers.

In our customers' production, the metal is required to have a density index below 1%. Aluminum is a preferred material for automotive manufacturers because it is light and flexible to work with.

Our customer stated that after a weekend without production (3 days) the metal in the furnace reached a density below 1%.

After a weekend of production, a customer reported that the test results showed 0,8% in the degassing section and 0,9% in the holding section without any degassing by rotary impeller.

The furnaces are equipped with degassing stones providing a volume of nitrogen between 1,5 – 2,5 l per minute, depending on the time of the year with high or low air humidity.

The DTI 6020 dosing furnaces with vertically immersed heating elements and degassing stones have provided excellent results for the customer in keeping a low metal density.

Essentially, the feedback discloses that our Dosotherm® DTI furnace has provided our automotive customer with optimal conditions and improvements in terms of use, material density, and -quality.

Our Dosotherm® DTI furnace has revolutionized aluminum dosing for good.

With its precise dosing abilities, immersion heater, and high-performance design, the DTI furnace sets new standards in dosing precision, safety, and efficiency.

Explore more about our Dosotherm® DTI here.

Leading German automobile manufacturer, Audi was looking for a modern, sustainable, and trusted way to create high-quality automotive parts in...

Ever since Volkswagen bought its first Støtek furnace in 2009, they have expanded their furnace capacity additionally, resulting in lower energy...

In the industrial sector, companies increasingly explore more innovative and sustainable solutions to reduce their carbon footprint and meet their...