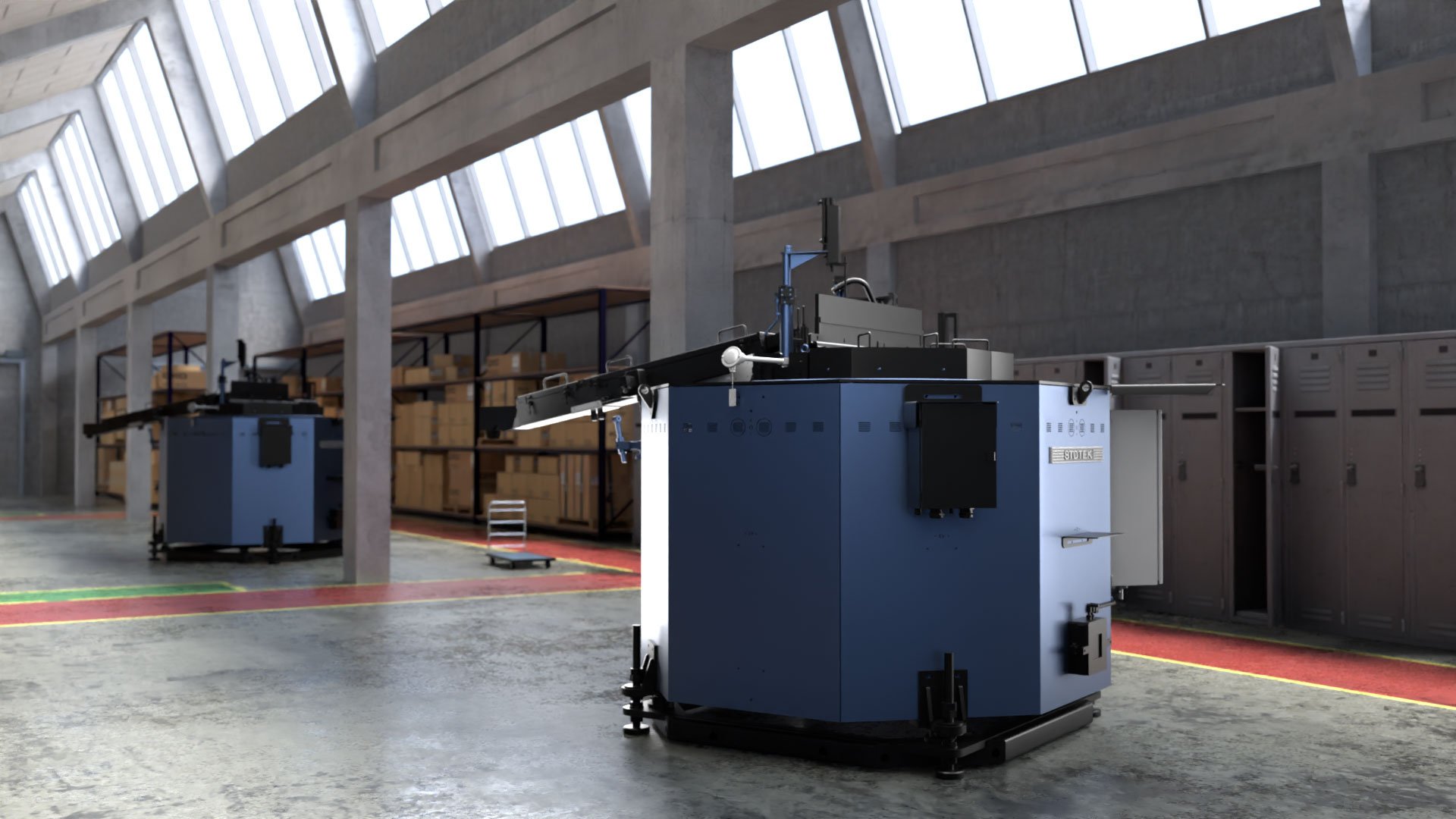

Discover the electric crucible dosing furnace (AMED)

Støtek introduces the DOSOTHERM® DTI — a cutting-edge dosing furnace that integrates precision dosing technology with immersion heating.

The AMED stands as an all-encompassing electrically heated crucible furnace, purpose-built for the seamless processes of holding, melting, and dosing aluminum. At its core lies a Støtek dosing unit, celebrated for its precise dosing capabilities (+/- 1% based on dosing weight), enabling doses of up to 25 kg/Al per shot. With a melting speed of up to 360 kg/Al/h, the AMED ensures swift and efficient operations. With the integration of our precision dosing technology, the metal and production improve in terms of quality, efficiency, and accuracy.

Crafted to guarantee superior metal quality, this furnace is particularly adept at handling special alloys containing sodium, strontium, or substantial quantities of magnesium. Its multi-layered high-efficiency thermal insulation translates into remarkably low energy consumption, aligning with sustainable practices.

The AMED, an all-in-one furnace, encompasses the benefits of the DTE model while additionally functioning as a crucible melting and holding furnace. Experience the fusion of precision, efficiency, and versatility in aluminum processing with the AMED.

Versatile Applications

With multiple configuration possibilities, these furnaces cater to various application sizes, accommodating individual layout requirements.

Tailored Configurations

Customize your furnace with a range of options:

-

Capacities from 600 kg to 1650 kg

-

Load cell for metal level measurement

-

A heated or nonheated ceramic launder system

-

Profinet and profibus communication

To further optimize and increase productivity and safety, a pre-heat station for the dosing unit and transport ladle and -heater can be considered.

Dosing furnaces

Crucible furnaces

Shaft furnaces

Holding furnaces

Transport ladle

Datasheets![]()