Audi chooses Støtek to increase their furnace reliability and metal quality

Leading German automobile manufacturer, Audi was looking for a modern, sustainable, and trusted way to create high-quality automotive parts in...

Ever since Volkswagen bought its first Støtek furnace in 2009, they have expanded their furnace capacity additionally, resulting in lower energy costs and saving the plant in Kassel thousands of Euros.

Volkswagen plans to decarbonize its production and make mobility climate-neutral with the new initiative 'Way to Zero'. They have taken numerous steps leading them towards becoming net carbon neutral by 2050. One of the initiatives in their production was to replace their old furnaces with new, more energy-efficient ones. This was where Støtek entered the picture.

10.000 Euros per furnace. That was the amount saved yearly at the Volkswagen plant in Kassel after replacing 10 furnaces with new furnaces from Støtek.

Volkswagen's new initiative for climate-neutral mobility - "Volkswagen way to zero"

Dr. T. Kreuzinger, Volkswagen

Dr. T Kreuzinger points out Støtek’s unique dosing system, which operates through a vacuum to ensure that the starting level is constant all the time. This allows accurate dosing of the metal dispensed and a higher metal quality.

Another advantage is that the Støtek furnaces only require minimal cleaning and that their design makes cleaning fast and easy.

Hosting Europe’s biggest die-casting foundry, and producing 5.96 million cast parts a year, the people at the Volkswagen plant in Kassel depend on production running as smoothly as possible. Therefore, superb quality and quick service are must-haves when choosing furnaces and other inventory for their production facilities.

Dr. T. Kreuzinger, Volkswagen

The Volkswagen plant in Kassel covers an area of 3,040,532 m2 and employs more than 15,500 staff members

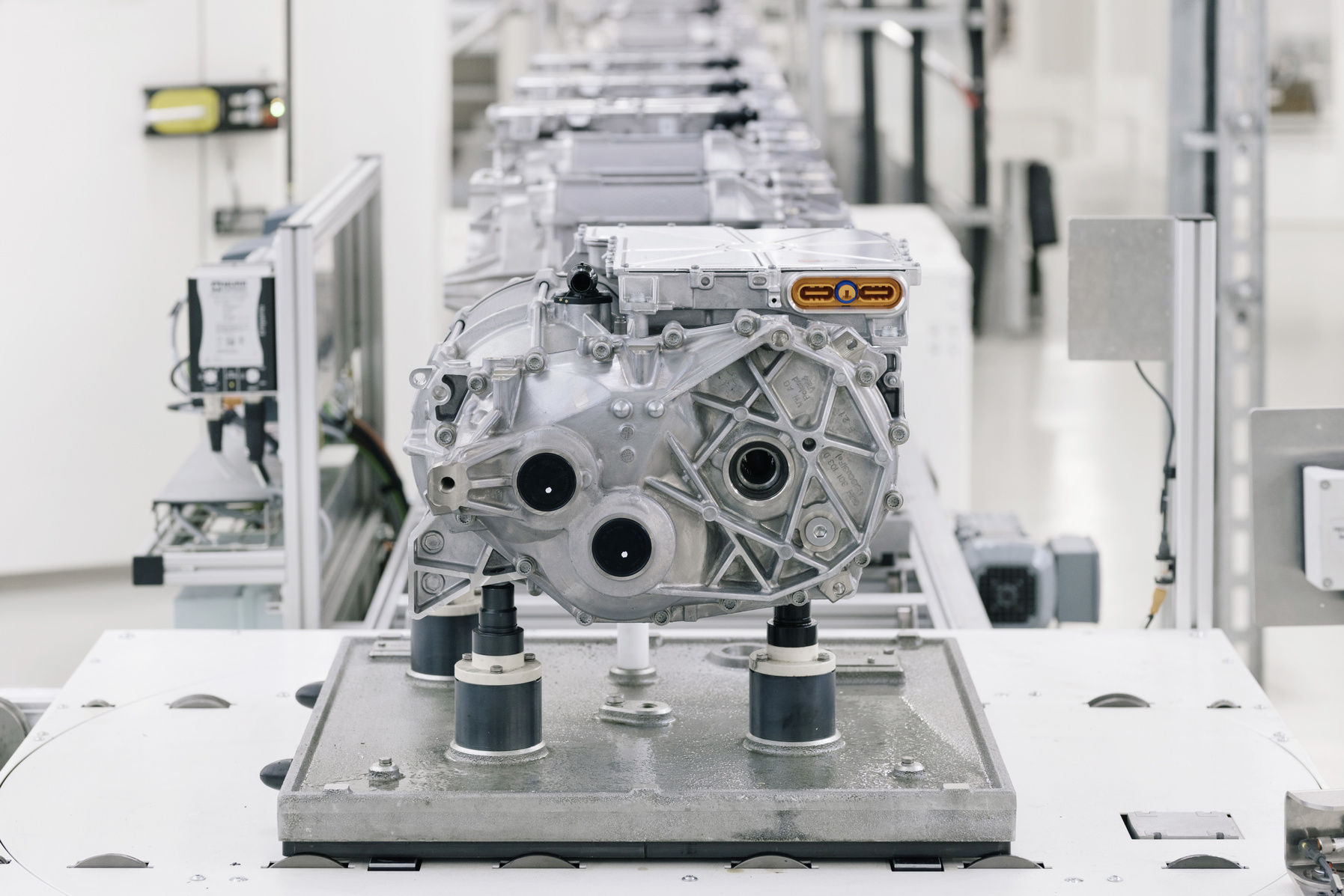

As the main manufacturer of gearboxes, the Kassel plant is one of the key component suppliers for the vehicle assembly plants operated by the Volkswagen Group around the world. In addition to manufacturing gearboxes, the Kassel plant supplies several other important vehicle components, such as exhaust systems and body parts.

In 2011 the plant manufactured approximately 3.6 million gearboxes and around 4.2 million exhaust systems. The press shop and body manufacturing plant produce some 1,300 metric tonnes of sheet steel every working day and make around 60,000 body parts each day and hot form hardening 24,000 parts each day.

There are multiple ways to cut your furnace costs additionally.

We wrote a blog post where we take you through some essential tips on how to control and decrease your furnace costs.

Read more here.

Leading German automobile manufacturer, Audi was looking for a modern, sustainable, and trusted way to create high-quality automotive parts in...

Støtek has years of experience working with the automotive industry, which has brought along a great amount of knowledge and insight as to what...

Støtek sells a minority stake to the investment company Industri Udvikling. The goal has been to find a partner to continue the company's global...