Støtek helps Volkswagen cut down energy costs

Ever since Volkswagen bought its first Støtek furnace in 2009, they have expanded their furnace capacity additionally, resulting in lower energy...

Looking into cost savings can have a significant impact on your business. In this article, we provide you with essential tips on how to tackle your foundry's energy hot spots by e.g. lowering carbon emissions and cutting energy consumption in your aluminum foundry to ultimately improve profitability and cost-efficiency.

Leveraging data becomes crucial in identifying areas for improvement. For instance, using furnace load cells to track material weight and energy consumption can unveil performance inefficiencies, especially in filling and distribution.

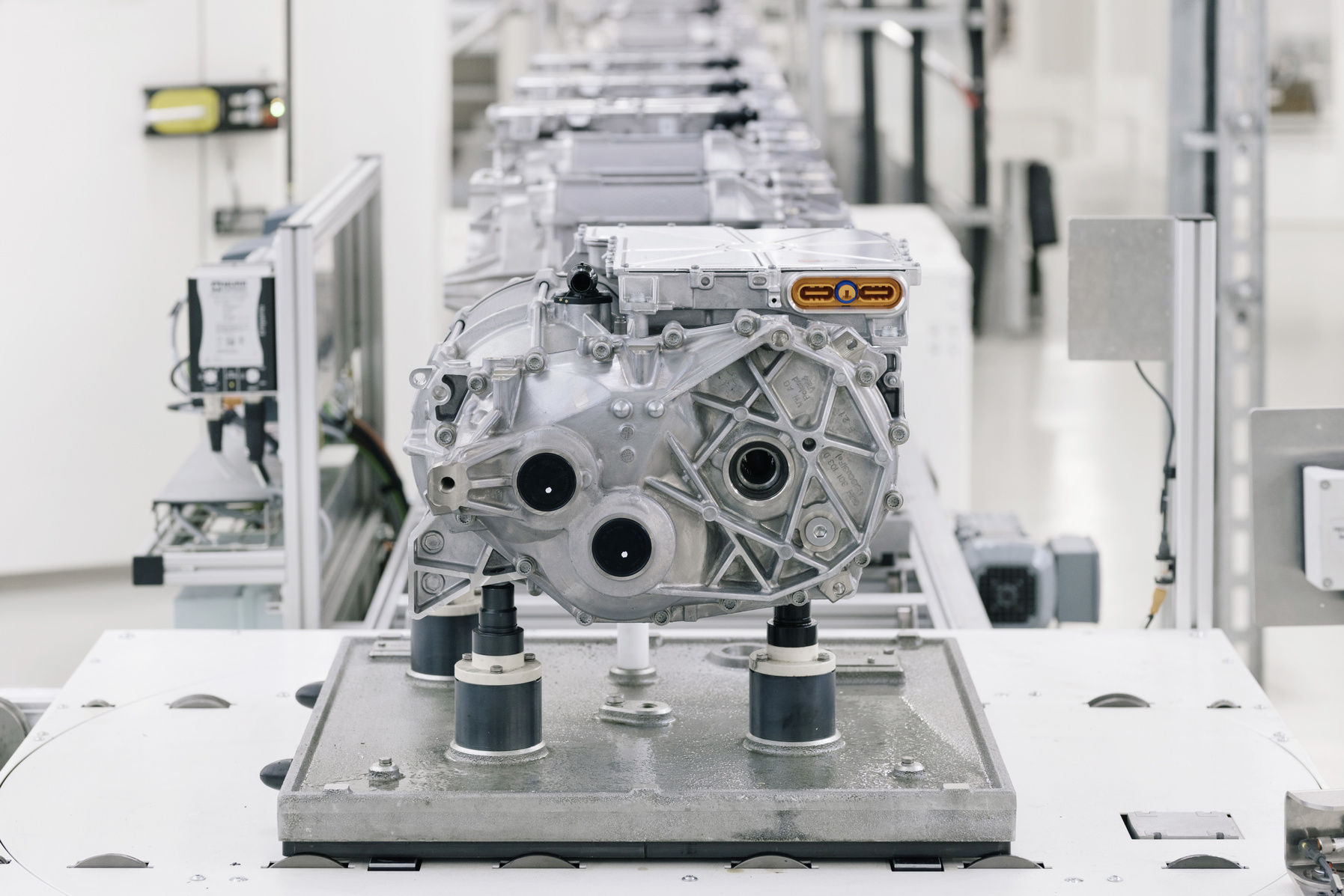

Shaft melting furnaces stand out as energy-efficient, employing a counter-flow principle to optimize the melting process. A balanced ratio of returns and ingots as well as the use of smaller ingots maximize energy use and metal yield.

Operating at a high capacity boosts energy efficiency, but it is common for foundries to melt below full capacity due to various reasons. Maintenance plays a pivotal role in curbing energy consumption, with small adjustments like maintaining furnace door seals, correcting spare parts, or optimizing burner efficiency, contributing to significant savings.

Efficient transfer systems, such as closed ladles and dosing systems, minimize heat loss and enhance metal quality, ultimately optimizing energy use and productivity.

Aluminum die-casting operations demand considerable energy, with about a quarter of the cost linked to energy usage.

The melt shop alone can gulp down as much as 77% of a die-casting foundry's overall energy consumption.

Ever since Volkswagen bought its first Støtek furnace in 2009, they have expanded their furnace capacity additionally, resulting in lower energy...

Efficient use of materials is key to cost reductions. When it comes to aluminum foundries, there are numerous strategies to cut costs. In this...

Støtek has years of experience working with the automotive industry, which has brought along a great amount of knowledge and insight as to what...