Shaft melting gas furnace (SMG)

Støtek introduces the DOSOTHERM® DTI — a cutting-edge dosing furnace that integrates precision dosing technology with immersion heating.

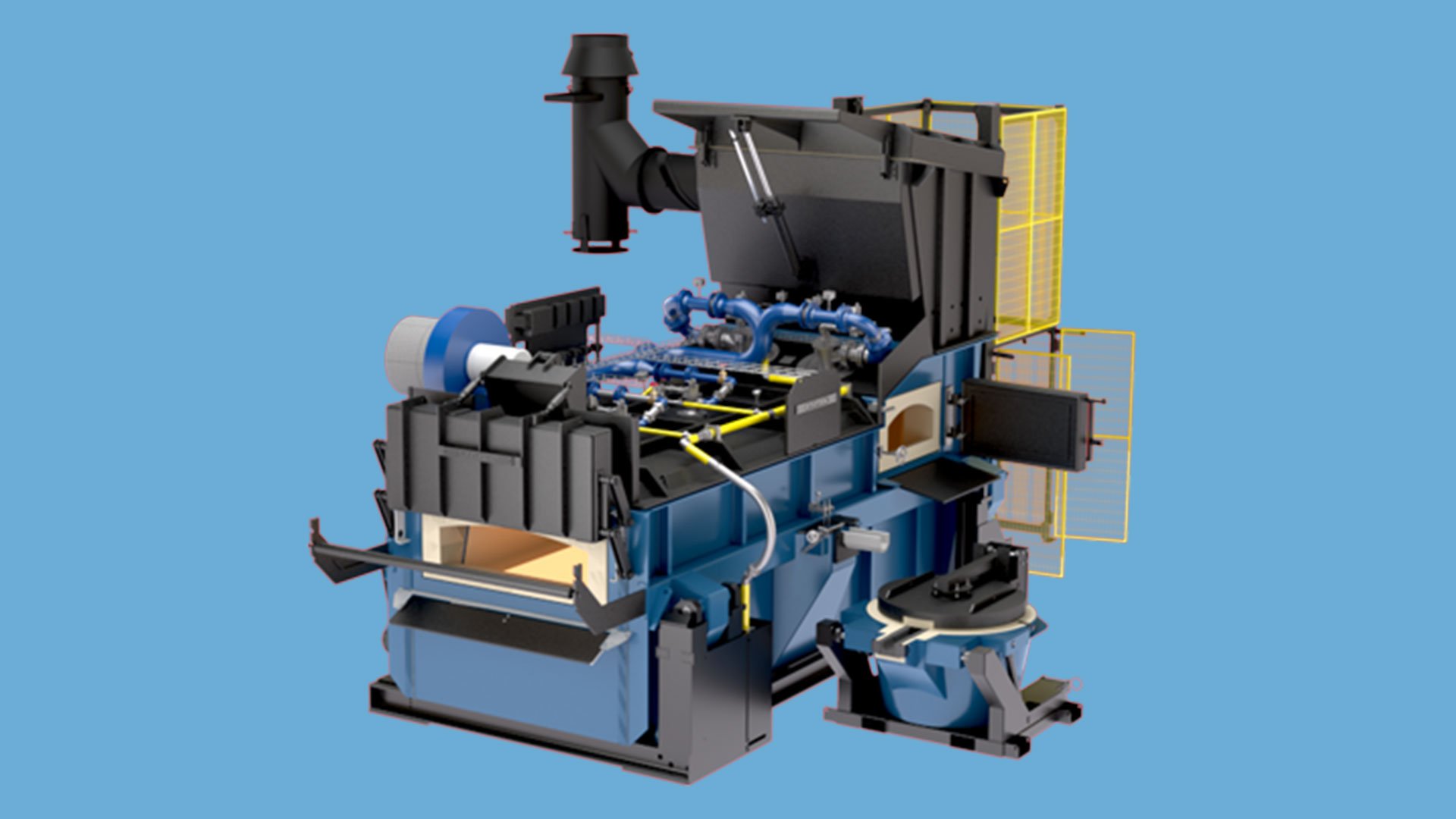

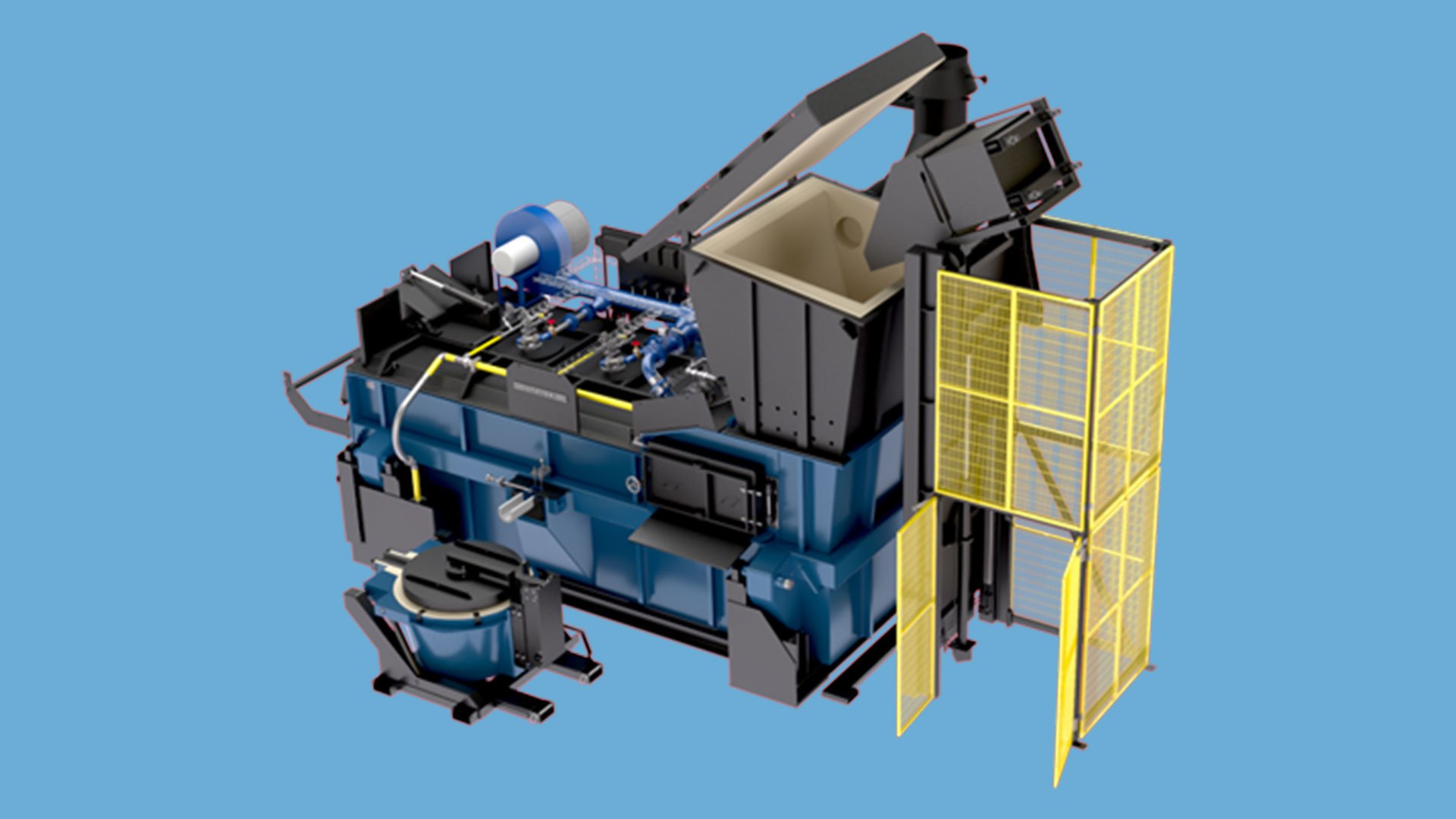

Støtek’s gas-fired shaft furnace is a fully automatic two-chamber melting and holding furnace. The modular build SMG models can be configured as:

SMGT with hydraulic tilting table for safe pouring of liquid aluminum.

SMGS with a static frame for pouring liquid aluminum through a tap cone or with a bale-out section for transfer with a ladle or pump.

Melting section: 1,0 to 5,0 tons melting capacity per hour

Holding section: 2,0 to 10,0 tons holding capacity

With multiple configuration possibilities, any size of application can be covered. This allows also for individual requirements for layouts for combining melting and holding sections, charging systems, and directions for loading material into the furnaces.

Together with Støtek dosing or holding furnaces, SMG shaft furnaces are used for in-cell melting in mega-casting applications or for central melting for distribution to the casting cells with transport ladles.

Main design characteristics

Støtek shaft furnaces SMG are designed with a very solid steel shield and lined with high-quality refractory products from leading manufacturers providing:

-

Long-lasting for increased lifetime

-

Optimal thermal properties for saving energy

-

Easier cleaning for saving maintenance cost

The lining geometry is designed as a straight wall lining adding further benefits for easy cleaning and maintenance. Very low oxidation is in focus in the burner and chamber layout.

Lectrical-operated cleaning doors ensure easy access for cleaning both the holding and melting chamber.

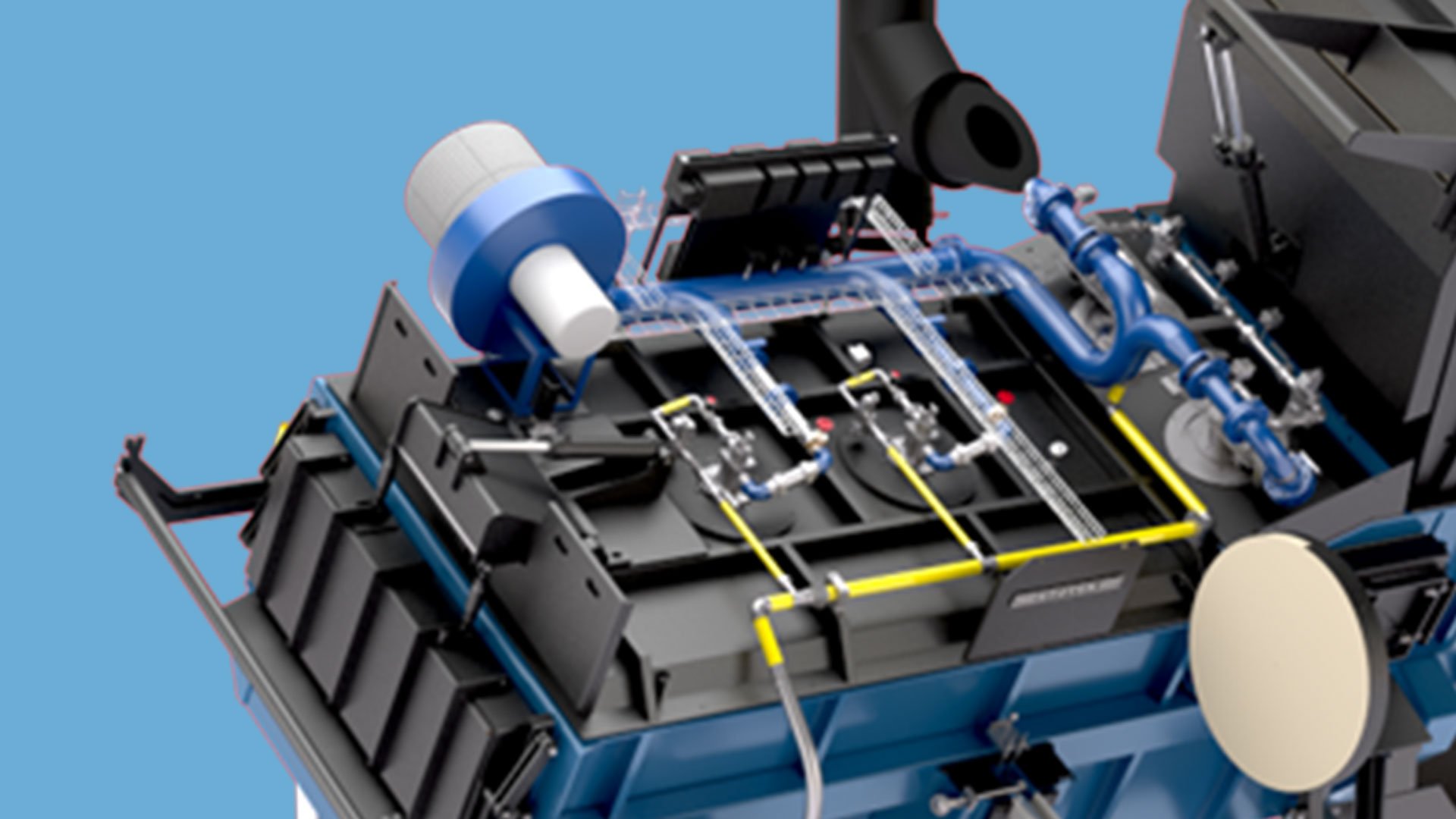

The melting shaft is designed for optimum energy exchange with the utilization of hot exhaust gas for preheating the metal with the automatic operation of an exhaust lid and a hood for collecting and re-using exhaust gasses.

Separate multiple burners for melting and holding sections secures an energy-effective process. Flat flame burners in the holding section provide an optimal solution as this type of burner does not have any direct flame onto the metal surface and thereby reduces metal burn and the amount of dross.

SMG Shaft furnaces are equipped with fully automatic charging systems for efficient and continued operation with minimum operator intervention. The charging system can handle both primary metal (ingots) and scrap metal.

In SMGT (tilting versions) lip axis pouring is ensured by having bearings aligned with the spout. A teapot spout provides accurate pouring and eliminates airflow through the furnace.

All Støtek SMG furnaces are equipped with a free-standing control cabinet that holds a 12” color touch panel with a graphical visual presentation of all key data and settings. A lamp tower is mounted on top of the control panel.

Configuring a Støtek SMG shaft melting furnace

Støtek recommends a two to three-times larger holding capacity compared to the melting speed to provide a high metal quality and secure optimal flexibility in operating the furnace. It will also contribute to an improved stable and accurate metal temperature in the holding section.

It is possible to choose between several options to configure the furnace to individual needs and requirements:

- Exhaust hoods over cleaning doors

- Movable and static cleaning platforms

- Bale out section and transfer pump solution

- Degassing stones

- Communication with plant surveillance systems

Dosing furnaces

Crucible furnaces

Shaft furnaces

Holding furnaces

Transport ladle

Datasheets![]()